Description

| Manufacturer | 3M |

|---|---|

| Brand | 3M Abrasives |

| Main Category | Abrasives |

| Weight | 2.4 lb |

Achieves Aggressive Cut with Smooth Finish, Resists Gouging

Ideal for use in metal fabrication, the heavy duty Standard Abrasives™ Zirconia HP Flap Disc achieves fast, aggressive stock removal without compromising finish. It is a great choice for high pressure grinding applications, especially on stainless steel when a nice finish and gouge resistance are desired. A grinding aid on the disc reduces grinding temperatures for best results and extended disc life in operations on stainless steel and steel alloys.

Outcuts and Outlasts Grinding Wheels and Fiber Discs

The overlapping layers of coated abrasive cloth flaps make this flap disc flexible, long lasting, sharp cutting, and a great choice for one step grinding and blending. In many instances it can replace grinding wheels and fiber discs, making it an advantageous addition to machine shops and body shops.

Compared to a grinding wheel, a flap disc cuts cooler, works faster, and is more user friendly. The phenolic resin disc plate cushions the disc and reduces disc vibration, producing optimal finish and greater operator comfort.

A flap disc will outlast a fiber disc while still providing an aggressive cut, so you can count on replacing it less often, which saves time and reduces consumables. It produces a smoother, more consistent finish, and won't curl up in storage as fiber discs sometimes do. Choose one grade coarser than the fiber disc you would typically use for your application for comparable results.

Disc Workhorse Offers Great Versatility

A Standard Abrasives™ Zirconia HP Flap Disc provides an effective solution for many different high pressure operations. Use it to:

- Accomplish high stock removal on corners and flats

- Remove rust or other contaminants

- Flatten welds

- Smooth out stubborn beads and burrs

- Perform heavy duty beveling

- Remove cutting torch slag from steel plates

A flap disc may also be used for paint prep on wood, although it won't leave the same smooth finish it achieves on metal.

Choosing a Flap Disc

We engineered Standard Abrasives™ Flap Discs with the industrial operator in mind – they deliver exceptional cut and long life. Variations in mineral type, backing and disc shape enable efficient abrasive solutions. By pairing the right flap disc with your unique application you ensure peak performance and market leading value. We offer discs with five designations (each sold separately):

- Zirconia GP: Ideal for low pressure grinding on flat surfaces such as weld touchups and surface prep; cotton backing

- Zirconia AP: Versatile disc performs well when you need one disc for a variety of applications; poly cotton backing

- Zirconia HP: More durable backing supports high pressure grinding such as beveling, deburring and edge chamfering ; grinding aid for stainless and high nickel alloys; polyester backing

- Ceramic: Faster cut than Zirconia on high pressure applications; cool cutting action reduces loading risk and discoloration; grinding aid for stainless and high nickel alloys; cotton backing

- Ceramic Pro: Fastest cutting; grinding aid, ideal for stainless steel and high tensile alloys; poly cotton backing

Designed for use on a right angle grinder, flap discs have a Type 27 or Type 29 profile.

- Type 27 Flat: Flaps are flush with a flat surface and ideal for generating a smooth finish on flat areas or outside edges

- Type 29 Conical: Flaps are angled to provide more aggressive cu

TOP BRANDS

Shop the most trusted safety brands at Enviro Safety.

PRODUCT SPECIALISTS

Got a question? Call and ask one of our trained Product Specialists.

FAST EASY SAVINGS

Get what you need. Save time and money. Let's do this!

CUSTOMER SERVICE

Yes, we answer the phone and reply to email. We're here for you!

CORPORATE ACCOUNTS

Setup an online account. Apply for credit. And more.

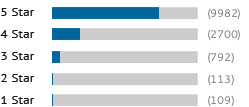

from this merchant give

them a 4 or 5-Star rating.